high quality submersible pump for slurry

Latest articles

- transport solids hydraulically

high quality submersible pump for slurry...

high quality submersible pump for slurry 【high quality submersible pump for slurry】

Read MoreChoosing the right target=_blank title=Slurry Pump>slurry pump for your application can be a daunting task. Slurry pumps can be found in almost all industries and play a vital role in many processes.The 4 key aspects to look for when determining the right slurry pump are slurry pump design, pump materials of construction, slurry pump seals, and proper slurry pump power sizing.Next, the target=_blank title=Slurry Pump Supplier>slurry pump supplier will share them with you.

high quality submersible pump for slurry...

high quality submersible pump for slurry 【high quality submersible pump for slurry】

Read MoreWe use CFD, CAD method for product design and process design based absorbing experience of world leading pump companies. We integrate molding, smelting, casting, heat treatment, machining and chemical analysis, and have professional engineering and technical personnel.

high quality submersible pump for slurry...

high quality submersible pump for slurry 【high quality submersible pump for slurry】

Read MoreIn a word, the wear-resistant properties of the slurry pumps are stronger, and the ability to convey particles is also stronger. Generally, the capacity of the slurry pump is larger than the mud pump, which is mainly used for coal and metal ore washing. The mud pumps are more suitable for abrasive slurry is not very strong.

high quality submersible pump for slurry...

high quality submersible pump for slurry 【high quality submersible pump for slurry】

Read Moretesting station in the world, and its test capacity can reach 13000m³/h. Annual output of our products is 10000

high quality submersible pump for slurry...

high quality submersible pump for slurry 【high quality submersible pump for slurry】

Read MoreLifetime use

high quality submersible pump for slurry...

high quality submersible pump for slurry 【high quality submersible pump for slurry】

Read MoreThe dredge pump is designed to draw sediment, debris and other hazardous materials from the surface layer into the suction pipe and transport the material through the pipe to the discharge site. The pump must be able to handle common solid debris of various sizes that can pass through the pump, thus minimizing the downtime required for cleaning.

high quality submersible pump for slurry...

high quality submersible pump for slurry 【high quality submersible pump for slurry】

Read MoreThe terms slurry pump and dredge pump can be used interchangeably.

high quality submersible pump for slurry...

high quality submersible pump for slurry 【high quality submersible pump for slurry】

Read MoreCompared to standard centrifugal pumps, centrifugal pumps optimised for slurry pumping usually have the following features.

high quality submersible pump for slurry...

high quality submersible pump for slurry 【high quality submersible pump for slurry】

Read MoreThe slurry weight or consistency determines the type, design and capacity of the slurry pump required. If you have any questions about the best pump for your application, welcome to >contact us today or request a quote.

high quality submersible pump for slurry...

high quality submersible pump for slurry 【high quality submersible pump for slurry】

Read More

Popular articles

- In harsh conditions with sand, sludge, rocks and mud, ordinary slurry pumps tend to clog, wear and fail frequently. But WA heavy duty slurry pumps are highly resistant to wear and corrosion, which means that the service life of our slurry pumps is better than other manufacturers' pumps.

- On the other hand, if the slurry is not only abrasive but also has a low pH, then a duplex stainless steel construction is preferable. This material is best suited for slurry pumps to withstand harsh materials (such as acids) while still having a high Brinell hardness.

- Slurry Pump

- - Reduced space requirements - Since submersible slurry pumps operate directly in the slurry, they do not require any additional support structures.

- Dredge Pump Features

- The terms flushing and quench, often seem to be confused or misused when discussing seal support schemes for , slurry pumps, . As the concepts of a mechanical seal cartridge and a filled seal cartridge are slightly different, I will discuss them separately and in turn.

Latest articles

-

Larger impellers made of more material. This is to compensate for the wear and tear caused by abrasive slurries.

-

Magnetite mixing

-

Choosing the right slurry pump

-

2.Pumping slurries poses several challenges and problems, but with proper engineering and equipment selection you can experience many years of worry-free operation. It's important to work with a qualified engineer when selecting a slurry pump because slurries can wreak havoc on a pump if not properly selected.

-

Slurry Pump Impeller

-

Longer maintenance intervals

Links

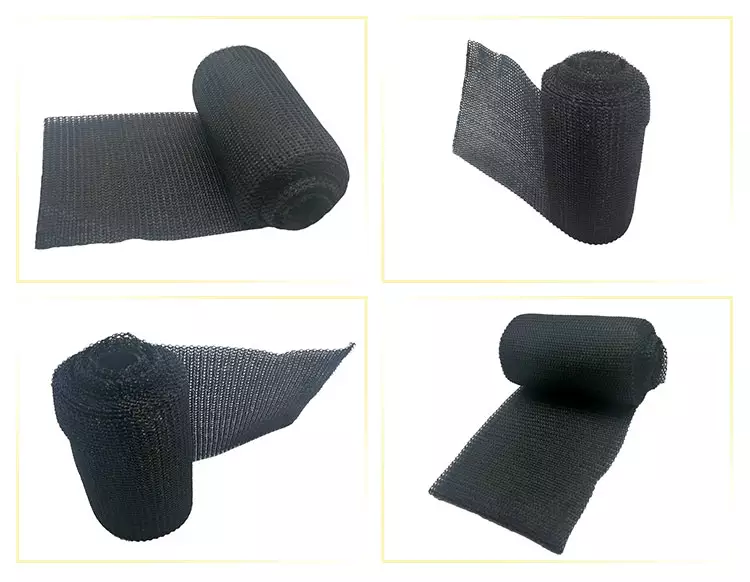

- Butyl rubber sealant, often referred to as butyl adhesive or butyl tape, is a highly versatile and durable material that finds extensive use in various industries due to its exceptional sealing properties. Its black variant, in particular, has become a staple in construction, automotive, and manufacturing sectors for its robust performance in sealing and waterproofing applications.

- The Industrial Revolution

Electrical tape is an essential tool for any homeowner or professional electrician. With so many uses, it’s no wonder that this versatile product is a staple in most toolboxes.

- Moreover, butyl rubber's high durability means that weather stripping made from this material can withstand years of use without cracking or breaking down. This longevity makes it a cost-effective solution in the long run, especially when compared to less resilient alternatives that need more frequent replacements.

- Step 2 Cut the Tape

- Minimizing Downtime: With all controls in one place, troubleshooting becomes faster, reducing downtime and maintaining productivity.

- In the vast realm of electrical applications, one often overlooked but crucial component is the insulating strip. These thin, adhesive-backed strips serve as a barrier to protect against heat, electricity, and sound. While they may seem inconsequential, their role in ensuring safety and efficiency within various systems cannot be overstated.

fabric electrical tape. By wrapping fabric electrical tape around exposed wires or connections, you can create a secure barrier that prevents shorts, sparks, and other hazards. This can help to prevent electrical fires and ensure the safety of your electrical system.

1. Durability

Prepare the Surface: Ensure the surface you're applying the tape to is clean and dry. This will help the tape adhere properly.

Butyl tape comes in single-sided and double-sided varieties, each of which is perfectly suited for specific tasks.

To achieve optimal results with butyl weather stripping, follow these simple steps

Selecting the Perfect Control Box for You

If you have any questions, don't hesitate to reach out. We'll do what we can to help.

adhesive cloth automotive wiring harness tape. Durability The combination of a cloth backing and a strong adhesive layer makes this tape highly resistant to wear and tear. It can withstand extreme temperatures, vibrations, and other harsh conditions commonly encountered in automotive environments.

adhesive cloth automotive wiring harness tape. Durability The combination of a cloth backing and a strong adhesive layer makes this tape highly resistant to wear and tear. It can withstand extreme temperatures, vibrations, and other harsh conditions commonly encountered in automotive environments.Efficient Organization

temporary floor marking tape

33 kv ht insulation tape.

In addition to its practical applications, the 130C linerless rubber splicing tape is also environmentally friendly. It is made from natural rubber materials, which are biodegradable and non-toxic. This makes it a sustainable choice for businesses looking to reduce their environmental impact.

Polyethylene Rubber Tape has several important characteristics:

self amalgamating rubber. The simplicity of use – applying the product and letting it cure in the presence of air – makes home repairs accessible and convenient for everyone.

self amalgamating rubber. The simplicity of use – applying the product and letting it cure in the presence of air – makes home repairs accessible and convenient for everyone.